|

meixinjiance

- 技术员

- 26

- 78

- 2015-03-11

|

1#

t

T

发表于 2015-03-11 13:53

|只看楼主

发表于 2015-03-11 13:53

|只看楼主

目的:óGò�`�sbbs.3c3t.com[¥8æû7,½p通过不破坏产品或零部件结构的方式,观察其内部结构、判断可能的失效模式,大多数样品测试后还可以继续使用。óGò�`�sbbs.3c3t.com[¥8æû7,½póGò�`�sbbs.3c3t.com[¥8æû7,½p常用的无损检测手段:óGò�`�sbbs.3c3t.com[¥8æû7,½p项目名称óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 用途óGò�`�sbbs.3c3t.com[¥8æû7,½p

| X射线透视检查óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 金属材料及零部件、塑胶材料及零部件、电子元器件、电子组件、LED元件等内部的裂纹、异物的缺陷检测óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 超声波扫描检查óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 电子元器件、LED、金属基板的分层、裂纹等缺陷óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 渗透探伤检查óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 焊缝、管材表面裂纹、针孔等缺陷检查óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 磁粉探伤检查óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 铁磁性材料表面裂纹、针孔等缺陷检查óGò�`�sbbs.3c3t.com[¥8æû7,½p

|

óGò�`�sbbs.3c3t.com[¥8æû7,½póGò�`�sbbs.3c3t.com[¥8æû7,½p典型应用图片:óGò�`�sbbs.3c3t.com[¥8æû7,½póGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

|  óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 连接端子内部结构X射线透视检查óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

| PCBA组件内部结构X射线透视检查óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

|  óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

|  óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 电池内部结构X射线透视检查óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 电池内部结构X射线透视检查óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

|  óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

|  óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

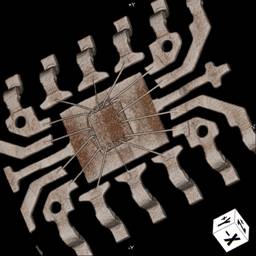

| 3D射线透视检查内部结构óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 3D射线透视检查内部结构óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

|  óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

|  óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

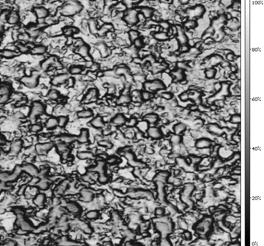

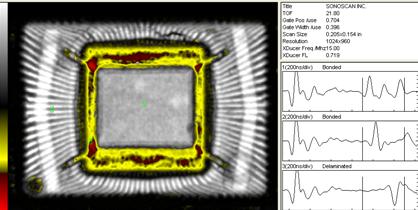

| 扫描超声波检查材料内部缺陷óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

| 扫描超声波检查材料内部缺陷óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

|  óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

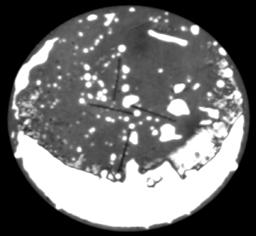

| 扫描超声波检查IC内部缺陷óGò�`�sbbs.3c3t.com[¥8æû7,½p óGò�`�sbbs.3c3t.com[¥8æû7,½p

óGò�`�sbbs.3c3t.com[¥8æû7,½p

|

óGò�`�sbbs.3c3t.com[¥8æû7,½p

|

%20(2)_1.gif)